We Provide Digital Cutting Systems

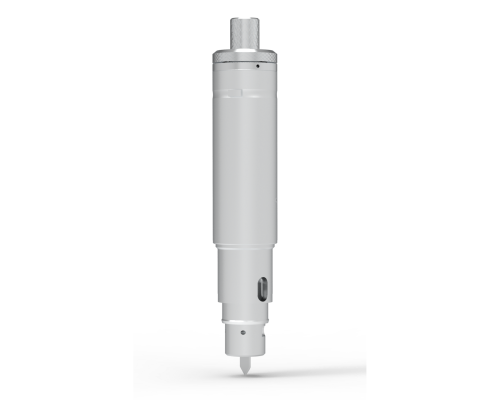

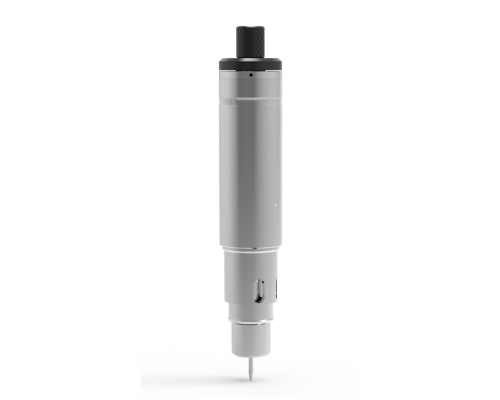

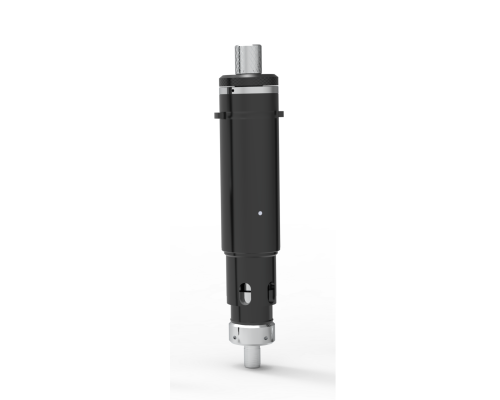

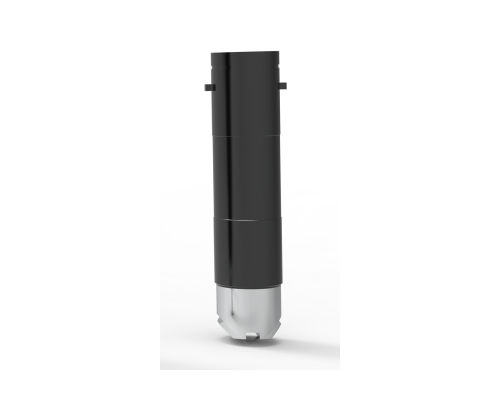

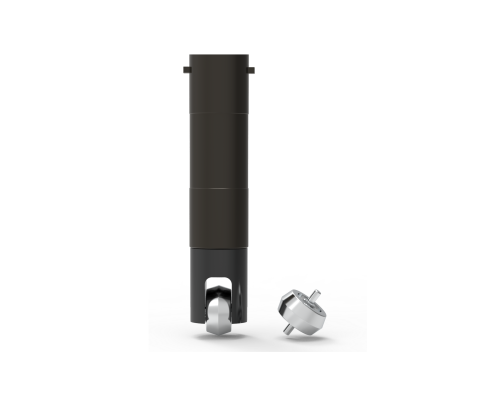

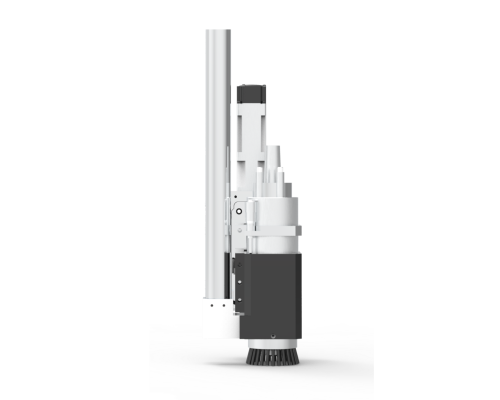

Multi-functional Working Head & Professional Tools

Our Clients

FAQs

Let's Crack Those Questions

Zingcut’s machines are tailored for industries such as footwear/accessories, apparel, technical textiles, signage/graphics, POS display production, packaging, furniture upholstery, vehicle upholstery, glass/carbon fiber, etc.

Our machines can precisely cut a wide array of materials including leather, fabrics, textile, paper, cardboard, corrugated cardboard, twin-wall sheets, wood, vinyl, plastics, rubber, foam, aluminum, and fiber-reinforced plastics.

Our machines are known for their top-quality, rich experience since 1995, strong R&D capabilities, prompt services, customizable functions, and breakthrough technology.

You can contact us through our website or email to discuss your requirements and receive a customized quote.

Industry and Application: Inform your industry and the specific application for which you need a CNC cutting machine.

Materials to be Cut: Specify the types of materials you intend to cut, including their thickness, width, length and characteristics.

Cutting Requirements: Outline your cutting requirements, such as precision, speed, and volume/production output.

Timeline: Specify your timeline for purchasing and installing the CNC cutting machine.

Space and Power Requirements: Provide information about the available space and power supply at your facility.

Contact Information: Provide your contact details for formal quotation, further communication and assistance such as company name, address, tel, email and contact person.

Yes, we provide training for operating and maintaining our machines to ensure optimal performance.

Both online and on-site installation and training are available.

Yes, we offer customization options to tailor our machines to meet the specific requirements of different industries and applications.

Despite the initial investment, our machines prove to be cost-effective in the long run due to their higher efficiency, better material utilization, and productivity advantages.

Still no luck? we can help!

Recent News

We're here to help

Fill out the form or call 650.800.3124.